Drivetrain Mechanical Design

We offer our customers a full design and development service for all parts of the drivetrain. Taking the initial concept, whether it is a new product or the adaption of an existing system, we have the capability to design:

- Casings

- Gear, shaft and bearing arrangements

- Couplings and disconnects

- Special purpose assemblies

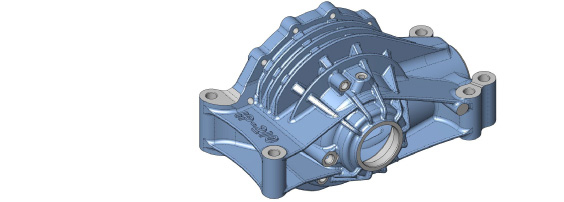

Casings

We have extensive experience of designing cast and machined casings, both for sand cast and die cast production methods. Patterns for sand castings and hard tooling for die castings are typically cut directly from our CAD data, which is also used to program the CNC tools that machine the finished parts.

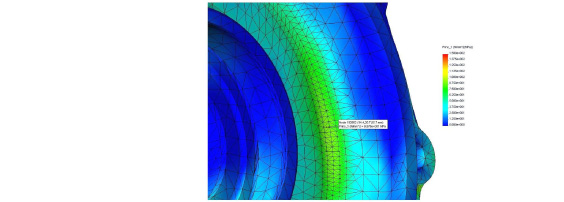

We have various analysis tools at our disposal, to ensure that the finished parts are fit for purpose, including:

- Draft Analysis

- Wall Thickness Analysis

- Finite Element Analysis

Cast parts will usually be subject to all of the above as part of our design work flow, with the depth of the analysis study being proportional to the complexity and significance of the subject part.

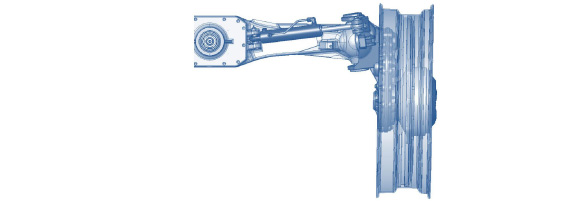

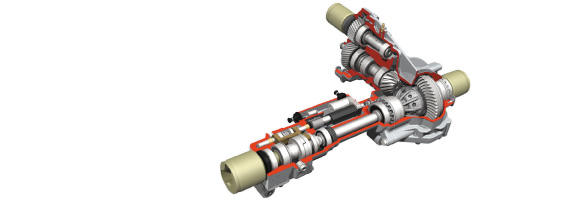

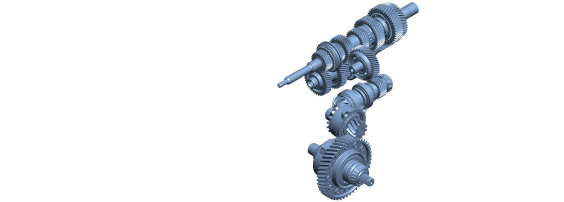

Gear, Shaft and Bearing Arrangements

Gears, shafts and bearings are an essential part of any drivetrain, and we have considerable expertise in this area. We have significant experience in the design of unique drivetrain arrangements, where packaging constraints rule out a more conventional solution.

Analysis

Our innovative designs are validated using a variety of analysis tools, allowing us to identify potential weak links in the system at the design stage and take remedial action ahead of the prototype phase. Our analysis tools include:

- Durability Analysis of complete drivetrains, subjected to application specific load collectives.

- Contact Analysis of individual tooth meshes, including shaft deflection, lead angle modification and transmission error prediction.

- Finite Element Analysis

- Classical Gear Analysis

- Spur and Helical Gear Analysis according to ISO 6336

- Bevel Gear Analysis according to ISO 10300

- Hypoid Gear Analysis according to Klingelnberg

- Classical Shaft Analysis

- Shaft Strength according to DIN 743

- Classical Bearing Analysis

- Bearing Life according to ISO 281

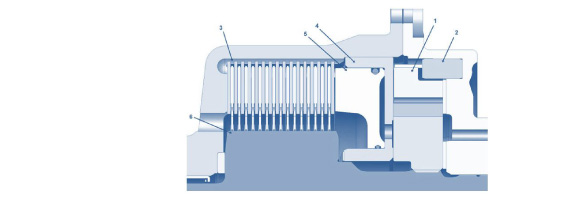

Couplings and Disconnects

Drivetrains often require some form of coupling or disconnect device, such that the correct parts of the drivetrain are connected to the power source at the appropriate time. Our experience in this field ranges from simple sliding dog devices, typically found in locking differentials and auxiliary axle disconnects, through to intelligent multi-plate clutch couplings, typically found in AWD systems.

We have been particularly successful with using multi-plate clutch couplings in innovative AWD vehicle drivetrain arrangements, and have seen some very impressive results in terms of dramatically enhanced vehicle off-road capability.

Special Purpose Assemblies

Our portfolio includes special purpose drivetrain assemblies, such as geared drop housings, which transform a standard axle into a portal axle, when exceptionally high ground clearance is required.